Automotive

- Vehicle interiors, exterior plastic-trim components and ‘under bonnet’ sub-assemblies (typically manufactured from injection moulded, vacuum formed or composite lay-ups) all require the application of Tappex® fastening solutions: Himoulds®, Triserts®, Multiserts® , steel threaded inserts for metal-alloys Trisert-3® . Additionally, Tappex also manufacture Compression Limiters which reduce the effects of ‘creep’ in thermoplastic mouldings, over time / elevated temperatures by providing ‘metal-to-metal’ contact along the axis of the bolted-joint and so resisting excessive application-tightening torques & resultant assembly joint-loads

- Under bonnet thermoplastic / composite material applications: injection-moulded manifolds, covers, ECU & fluid-pump enclosures. Often these applications require higher tensile strength performance from mechanical fasteners to cope with point of vehicle assembly installation torques. Tappex solution: forged steel SplayMoulds® installed by moulding-in and specified to 8.8 grade tensile strength

- OEM body-in-white / driver controls / Electro-mechanical assemblies are frequently specified with Tappex® threaded inserts for thermoplastics and, for more critical applications, patented Trisert-3® family of steel threaded inserts. Tappex® offer also to ‘vision sort’ fasteners using bespoke optical / laser-based equipment.

Aerospace

- Demanding, precision-engineered solutions, from Tappex® typically as a tier-2 / 3 component supplier, for a variety of aircraft applications including: business & 1st-class seating, toilet & kitchen installations that use composite glass & increasingly carbon-fibre, laminated constructions – Tappex® Trisert-3® stainless steel threaded inserts (303 & 316 grades) in either metric or imperial threads

- Bespoke customer specifications supplied also include 2D & 3D rapid prototypes, design guidance & in-house mechanical tests supporting the specification of threaded inserts even for satellite-equipment hardware applications

Consumer Goods

Electronics

- Serving both OEM’s and their contract moulding / sub-assembly manufacturing operations

- Tappex® can support low volume applications with its comprehensive range of brass thread inserts: HiMoulds®, Multiserts® or Triserts® along with bespoke Tappex® installation tooling for either manual or semi-automated placement (Electrically or Pnuematics activated)

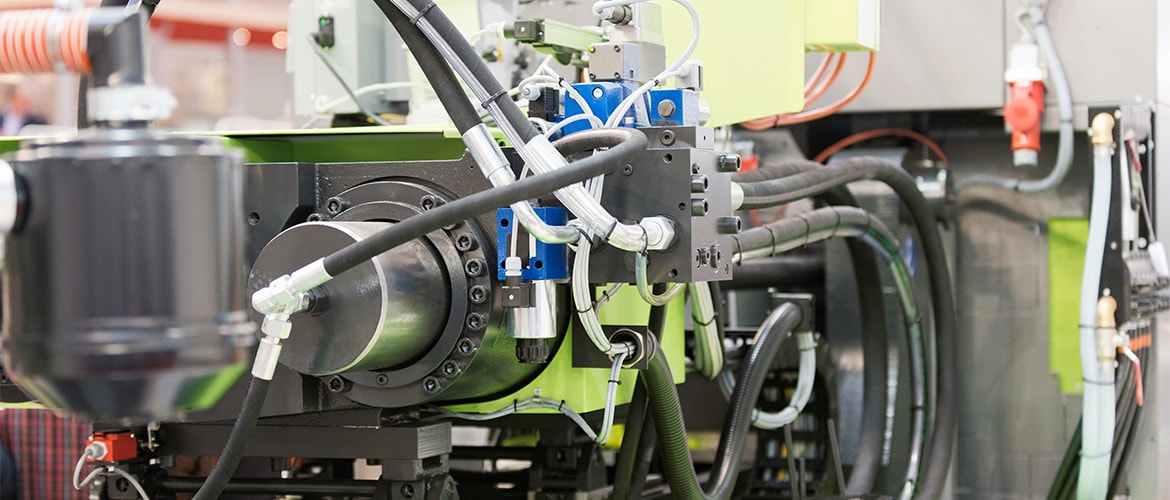

Machine Tools

- For many years Tappex® have supplied both brass female and male threaded inserts for Thermoplastics ‘compression-moulding’ whether in-mould or post-mould application

- For critical industrial / hydraulics / rotating machinery applications with a background of high vibration, Tappex® Pin-Lok steel threaded inserts offer features to ensure no loosening and maximum security when installed

- Parts for safety critical applications are often ‘vision sorted’ to check compliance with customer specific size / feature requirements

- Tappex® Threaded inserts are specified in metric, unified and also British Standard forms i.e. BSW/BSP/BA

Marine

- Whether for commercial, rescue, leisure or submersible-craft, Tappex® provide high-quality fastening solutions, backed up by comprehensive ‘in-house’ technical knowledge to meet the application demands: interiors, structure or external-mounted equipment

- Specifically Trisert-3® threaded inserts in either 303, 316 grade stainless steel and now Titanium (Ti5 grade) for exterior fitments / installation; brass inserts Multiserts® for navigation buoys & boat-interiors, Foamserts® self-threading inserts for interior wooden furniture and trim items, as well as the MultiRiv® Rivetnut designed for composite-materials & GRP panels (low force/wide grip-range rivetnut)

Medical Equipment

- We supply both brass & stainless steel (303 & 316 grades) press-in and self-threading brass & stainless-steel thread inserts for plastics to SMC processors, for example:

- ‘Body scanner’ applications

- ‘Ventilator equipment ‘ used for: anaesthesia delivery; airway management; suction control and oxygen therapy.

- Tappex® thread inserts are specified for RIM moulding processes; both standard & customer-special threaded inserts are available as well as for 2D & 3D rapid prototyping

Motorsport

- For exacting performance requirements & technical support, Tappex® serve many different motorsport categories including Formula One with threaded inserts (now including high strength / low weight variants machined from Titanium), compression limiters and special rivet nuts

- Whether for composites, vacuum-form, GRP, machined thermosets, light metal alloy constructions and increasingly 2D & 3D rapid prototypes, Tappex® threaded inserts have been the professional choice for over 30 years

Rail

- Composite panels and infusion moulded bespoke parts fastened with Tappex® in-mould and post mould brass threaded inserts; passenger carriage furniture is frequently specified with our brass Foamserts® thread inserts for woods and high-density foams alike

- Interior packaging, passenger carriage constructions, window frames and door/access (aluminium fabrications), fastened by Tappex® thread inserts, engineered for reliability and long life including Trisert-3® thread inserts in both case hardened steel & stainless versions (metric sizes 3 – 12mm along with unified & male geometry variants)

Telecommunications

- Many global customers and network’s applications served by Tappex® for injection-mouldings, aluminium die-castings, aluminium machined parts (equipment racking) as well as GRP enclosures being fastened together with our brass Triserts® & stainless steel Trisert-3® thread inserts

- Both on the ground and in satellite orbit around the earth, Tappex® thread inserts are to found holding vital functional parts together in demanding & occasionally remote environments!