About Us

Tappex Thread Inserts Limited is a UK-based company and is part of the privately owned Tappex group of companies established for over 60+ years serving both UK and International manufacturing supply chains and OEM customers alike, from their Stratford upon Avon HQ. Tappex has wholly-owned subsidiaries located in the UK, Sweden (Tappex Sweden) & Finland (Tappex Finland); Tappex also has a well-established global network of independent technical distribution-partners & sales agents since 1980’s.

We are specialists in the manufacture of threaded inserts for plastics, woods, light metal alloys & composite materials and provide high level technical advice and exceptional customer service. Our in house applications engineers and technically qualified field-sales staff are here to help our customers achieve cost effective solutions for thread insert applications across a wide range of industries, helping customers solve fastening problems by design, quality and service.

Products

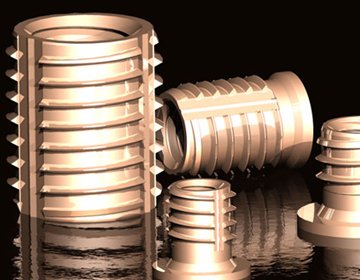

Tappex® offers a broad range of threaded inserts for plastics to suit mould-in and post-mould installation dependant on the customer’s application requirements as well as their in-house manufacturing process

considerations.

Tappex® have thread inserts designed for critical applications in light-metal alloys such as: Aluminium, Zinc & Magnesium when they are subsequently manufactured as castings, extrusions, machined or fabricated parts.

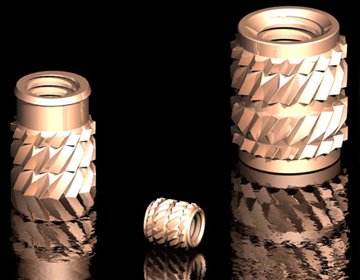

Tappex®, as a fastenings technical-leader, has identified bespoke requirements for mechanical joining of contemporary materials such as glass-reinforced plastics (GRP), combinations of metal alloys / plastics, structural foams / woods / paper-based sandwich constructions and increasingly carbon / kevlar-fibre laminated constructions.

For applications where stress-prone or brittle, glass-filled thermoplastics are specified, Tappex have developed special-variant threaded inserts to suit these more demanding materials. Such threaded inserts can be supplied either in either brass or steel material(s) for post-mould ‘self-threading’ and/or ‘press-in’ installation. Typical applications are either machined or moulded plastic(s) applications at ambient temperature or installed with heat applied.

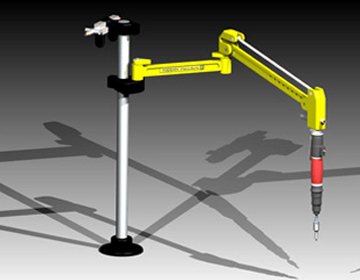

The Tappex range of installation tools includes: FlexiArm® (035 series) , Production drivers (029), Hand tools (030/031 series) and a 3rd generation heat installation machine to be introduced early November 2019. Our installation tools enable the installation of threaded inserts by either heat press-in or self-tapping (threading) methods.

Samples

Tappex can supply samples to suit your application and / or initial assessment needs. To request samples, please choose a product then configure it to your specification using our product selector, then choose Order sample /quotation form details. If the part nos are in stock then we typically will despatch in 1-2 working days upon receipt of your request.