Self-Tapping Inserts for Use in Laminated Table Tops

The Brief

The customer was using cold press fitted inserts into a core compact laminate table top. They were experiencing insert failures with their current inserts. Tappex were approached to provide a self-tapping alternative; testing was required to provide comparison to their current insert.

The Solution

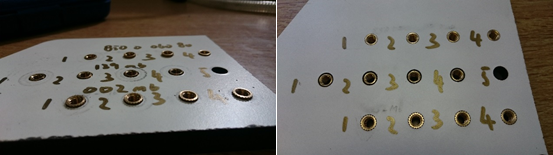

The customer provided a sample table top for testing to be conducted on, a sample of 4-off Brass Trisert 139M6 and 8 competitor cold press fitted inserts were installed. The Tappex Trisert was used as comparison to competitor’s cold pressed inserts.

The inserts were then testing in “Jack Out”, this means that the insert is totally unsupported and represents a worst case scenario. The jack out figures were then converted to a pull out force.

The competitors cold press fitted inserts(imported from Asia) failed in the region of 250 Kgf, whereas the Triserts failed ultimately in the region of 525 Kgf. Showing a significant increase in performance and the customer has since started to source from Tappex.

Tappex also offer a range of installation equipment for their own-manufactured self-tapping inserts.